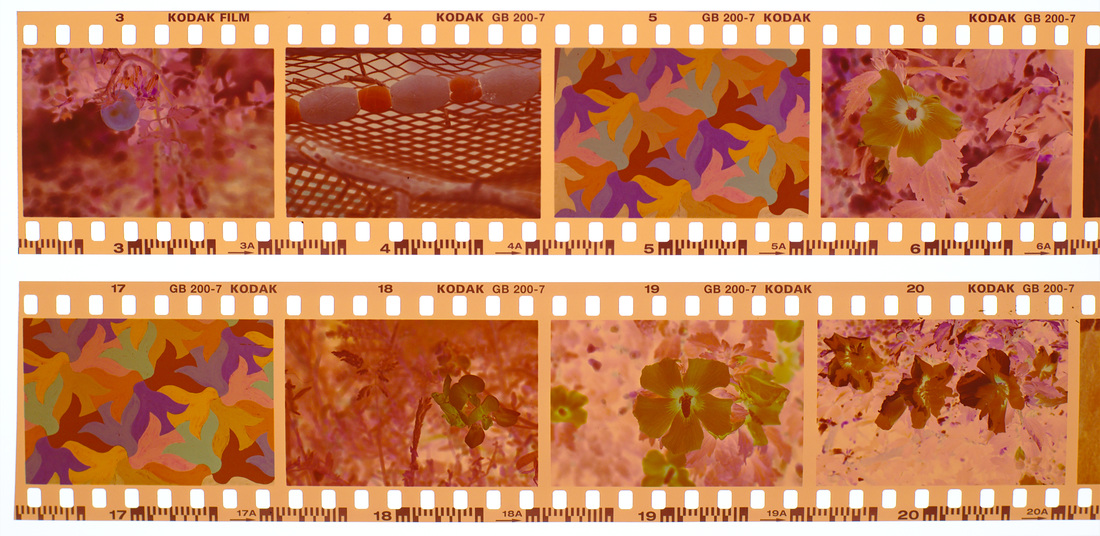

| A few examples of C-41 processed images | When I started shooting film again, I was mainly intending to do black and white because I knew I would be able to do all the processing and printing myself. However, it turns out that processing color negative film is quite easy as well. Printing is probably more tricky (and I do not have the equipment for it) but since I am scanning the film it is not an issue. Unlike for black and white film, there are not so many options for processing C-41 film and all film types are actually processed in a standard way (same chemicals, same times, same temperature, etc). That makes processing color film quite a bit simpler than black and white! In this post, I'll try to go through the process I use to develop C-41 and summarize the experiments I have made in order to get to that process. Context: (i) I am not processing high volumes (maybe one roll per week on average), (ii) I want to process the film as quickly as possible after shooting (I do not want to wait having 15 exposed rolls to develop them), (iii) I do not want to compromise image quality and (iv) I want to keep the cost of processing as low as possible (of course!). |

(My) C-41 Development Process

| I am using Tetenal Colortec kits for C-41 development kit for color negative film. I have been using a couple of 1L versions of the kit but I am now using a 5L kit and mixing 1L at the time. The kit contains 3 chemicals in liquid concentrate form (Developer, Blix and a Stabilizer) and a set of instructions for mixing the chemicals and processing film. All my developing has been done with these chemicals but this is just because that is the one I could get my hands on. I have no idea how it compares with other kits but I expect that most of the points I am discussing here would apply more or less the same with other chemicals. In addition to the supplied chemicals, I use a stop bath made of 2% acetic acid (diluted white vinegar). I re-use the same stop bath several times but change it when it starts to get yellowish/brownish because of being contaminated with developer. |

- Prepare a water bath at 30°C to bring all chemicals to temperature (Developer, Stop, Blix and Stabilizer).

- Load the film in the developing tank and put the tank in the 30°C bath as well for about 5 minutes.

- C-41 Developer at 30°C for 8'00" with agitation the first 15s (with twisting the stick) and 10s (3 inversions) every minute. Tap the tank and put it back in the 30°C water bath after every agitation. To account for the Developer being re-used and slightly diluted, after the 5th batch developed with the same 1L of developer, I increase the time to 9'00" instead of 8'00". I dispose of the chemistry after the 10th batch.

- Stop bath at 30°C for 0'30" with continuous agitation (with twisting the stick).

- Blix at 30°C for 6'00" with agitation the first 15s (with twisting the stick) and 10s (3 inversions) every minute. Tap the tank and put it back in the 30°C water bath after every agitation.

- "Ilford" wash with tap water at 30°C. 1 inversion + dump. 5 inversions + dump. 10 inversions + dump. 20 inversions + dump. 20 inversions, let it sit one minute + dump. Repeat the last if the wash water is not clear (with some film it is necessary).

- Stabilizer at 30°C for 1'00" with slow continuous agitation (with twisting the stick).

- Hang the film to dry. I do not use and squeegee but sometimes remove some of the liquid from the film by squeezing it between two fingers. I have not decided what the best strategy is as far as some possible drying marks vs some possible scratches but that is not specific to color negative film :-)

Temperature: why use 30°C instead of 38°C ?

| The recommendation from the instructions are to use a temperature of 38°C in a rotary processor. The times for processing are short which allow processing film quickly. However, in case of uneven development the instructions recommended to use lower temperature (30°C) and longer times. As far as I can tell, the only "disadvantage" of the lower temperature option is the longer time it takes to process film. The big advantages however are (i) not risk of uneven development even with manual agitation (ii) much easier to get accurate timings because of the longer times and (iii) easier to get a consistent 30°C temperature compare to 38°C (because it is closer to room temperature and cools off much slower). From this, unless developing with a rotary processor and in a big hurry (really ???) I would always choose the 30°C option and recommend using 30°C for developing C-41 "manually" |

Agitation: Manual vs. Rotary Processor?

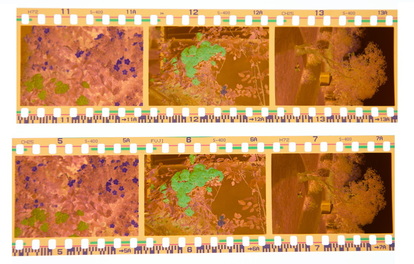

| The instructions are written mainly for using a rotary processor so it is easy to jump to the conclusion that you need a processor for C-41, however, this is not the case at all. The thing is that when using 38°C the development is so quick that agitation needs to be perfect in order to get even negatives. This is not so much of a problem when using lower temperatures and longer times. To check this, I made my own experiment and developed two pieces of the same film at the same time, using the same chemical and same 30°C temperature but one in the Jobo processor and the other one manually agitated with my usual agitation scheme of 15 sec twisting and 3 inversions every minutes. The picture on the right shows the result. The top 2 strips were developed with the Jobo processor (continuous agitation) and the two strips on the bottom were developed with manual agitation (15 second of twisting and then 3 inversions every minutes). The pictures on this test roll are not exactly the same so it is hard to compare very small variations. Overall the density of the negative are really really close. |

With or Without pre-wash / pre-soak?

I was a bit skeptic about the dilution issue at first but with a little experiment and calculation, I am now convinced and that is the reason why I do not pre-wash when developing C-41 film. To know how much the developer is potentially diluted a simple experiment of measuring how much of the pre-wash water actually comes out allows to estimate what is left on the film and in the tank. For 500mL of water poured in my tank containing either 1 roll of 120 or two rolls of 35mm, only between 475mL and 490mL come out of the tank. That means that between 10mL and 25mL are left on the film. When adding the developer, this small amount of water gets mixed with it. If using a one shot developer or using you 1L in 2 or 3 development batches, the effect of this dilution is quite negligible but I intend to reuse my 1L of developer for 10 batches or mores! that means that in the end a total of between 100mL and 250mL (!!!) of water ends-up being added to the developer. That is really significant and would for sure lower the developer concentration enough to affect the results.

Remark: Some recommend the pre-soak to make sure that the developer spreads more evenly and avoids bubbling on the film. While this may have been true at some point in history and with some specific films, I really haven't seen anyone reporting issues with bubbles or uneven development when doing a normal initial agitation and taping the tank to dislodge bubbles directly with the developer so I am not including it as a benefit here.

Why use a Stop bath?

The stop bath I use is 2% acetic acid (i.e. diluted vinegar) it helps get the developer off the film and greatly dilutes and neutralizes the developer left in the tank. Of course when pouring out the stop bath, 10mL to 25mL remain in the tank and ends-up diluting/contaminating the Blix but the acid of the stop bath is not as bad for the Blix as the alkaline developer would be. Based on this, I believe that it is very important to use a stop bath if you intend to re-use you chemicals for many batches.

I make my Stop bath by diluting white vinegar to 2%. In the shops the typical kitchen white vinegar is 7% or 8% but I also found some around 30%. Typically, I make a new stop bath solution every 4 or 5 batches or whenever it starts to have a brownish tint to it. The reason I use vinegar is just because it is cheap and widely available but any stop bath would do. In terms of preserving the Blix, using plain water as the stop bath would do the job almost as good but at least in theory the acid of the stop bath helps to neutralize the developer.

No wash / rinse after the Stabilizer!

You may choose to replace the stabilizer by another wetting agent (for example Photo-Flo) but in that case there is no point in using the Stabalizer before since you are just washing it away and with it all its potential benefits. From my understanding in short term you will not see any differences but in the long term (after many years) color negative film is prone to mold growing on/in it and that is what the Stabalizer prevents in addition to being a wetting agent. That is why I use the Stabilizer for C-41 and not Photo-Flo which I use for black and white film.

Remark: In case Stabilizer leaves drying marks on the film, one option seem to be to add some Photo-Flo to it. I have not had any problems with drying marks so I have not tried. I believe that the Stabilizer (at the the one I am using) already contains a wetting agent but I am not 100% sure and maybe in some case it helps to add more.

Example usage log for a Colortec C-41 1L kit

|

Conclusion: This experiment shows that in this case, I was able to process 14 rolls of film, in 10 batches distributed over 4 month and that there was no measurable difference in processing quality between the first and last roll that was developed. Keep in mind that this is of course just one example.

How long and how much the chemistry can be reused?

In terms of the number of batches, the instructions are not very specific but mention a maximum of 3 batches when processing film over ISO 400. That probably means that 5 or 6 batches can be recommended with film under ISO400. The number of batches is really something I want to be able to stretch because (i) I want to develop film as I shoot it and (ii) my biggest developing tank can only hold 2 rolls of 120 or 3 rolls of 35mm.

In summary, here is what I currently do:

- Change my chemicals after 5 month / 15 rolls / 10 batches whichever comes first.

- Test my chemistry whenever I have doubts or need to develop an "important" roll of film.

How to test if the chemistry?

Conclusion

Links

- TETENAL C-41 Rapid Negative Kit Review: Experiments showing the differences in the results obtained when developing with manual agitation at 38°C and 30°C. This review is the reason I went for 30°C right away.

- Home Processing of C-41 Color Negative Film: Some good description of the development process step by step. And a discussion on adding FotoFlo directly in the Stabilizer if you experience drying mark. The article claims that the Stabilizer does not contains a wetting agent. My impression is that the one I am using contains one and I have not experiences any troubles with drying marks but that may be something to keep in mind.

To get a better feeling of the process, there are also quite a few videos on Youtube from start to finish. Here are a couple which I have watched before getting started

- Developing Color Film (C41) by The Art of Photography: Shows the process of developing with manual agitation and a simple water bath to keep temperatures.

- How To: Develop Color Print Film (C-41 Process) by ForesthillFilmLab: Processing C-41 with a Jobo processor.

- Color Film Processing by The Rescued Film Project: Processing hundreds of rolls manually !!!